Powerful solution for machine maintenance < QC20-W ballbar system > vol.1

.png)

In machine tool performance diagnosis (dynamic accuracy)

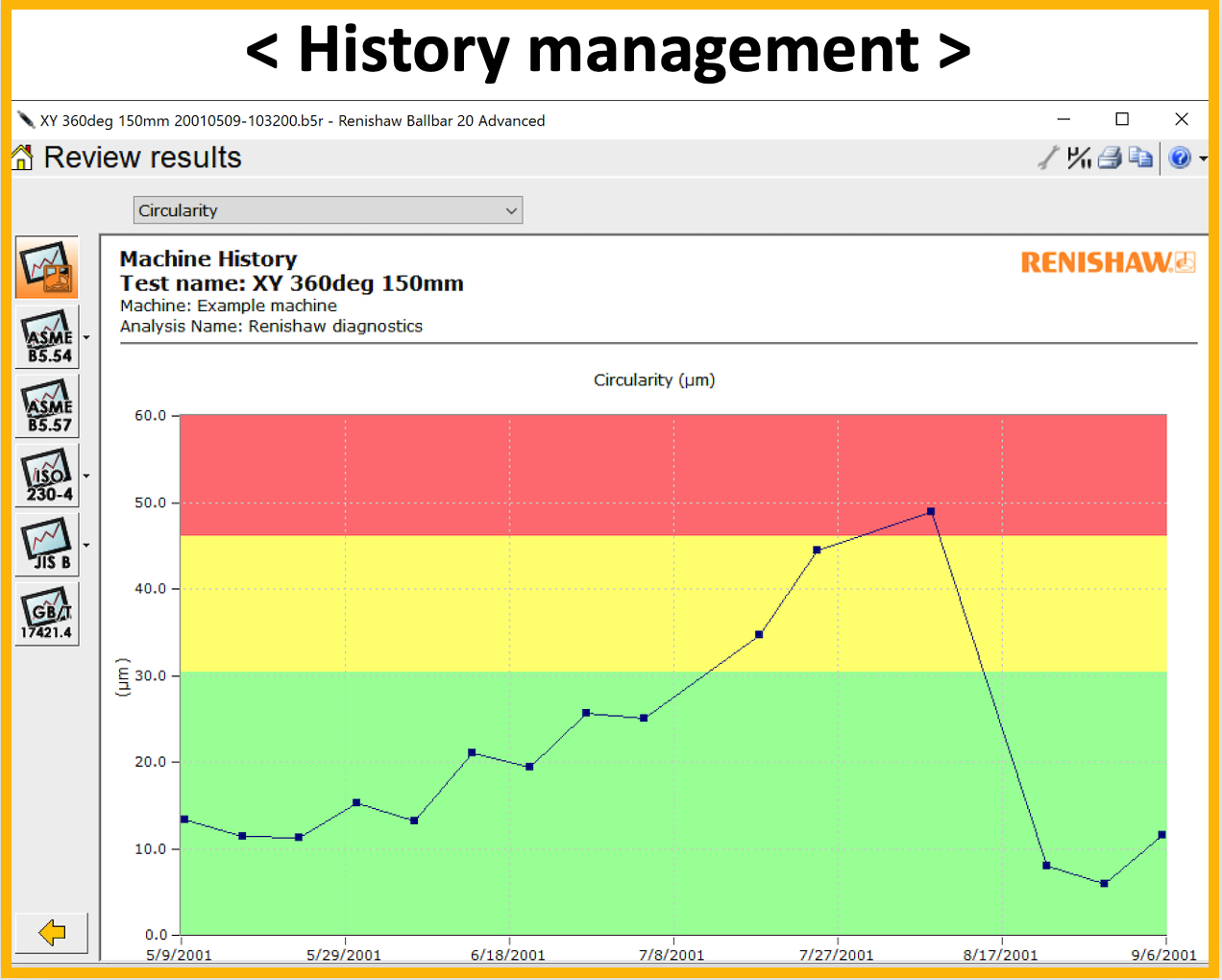

Double Ballbar testing provides a simple, rapid check of a CNC machine tool's positioning performance to recognised international standards (e.g. ISO, ANSI/ASME etc) allowing users to benchmark and track the performance of their machines and to quickly diagnose problems that may require maintenance and the error sources that produce them.

The system that makes this possible is Renishaw QC20-W.

Ballbar testing has three step processes, 1) Set-up, 2) capture data, 3) analysis.

Benefit of QC20-W :

- Easier set-up.

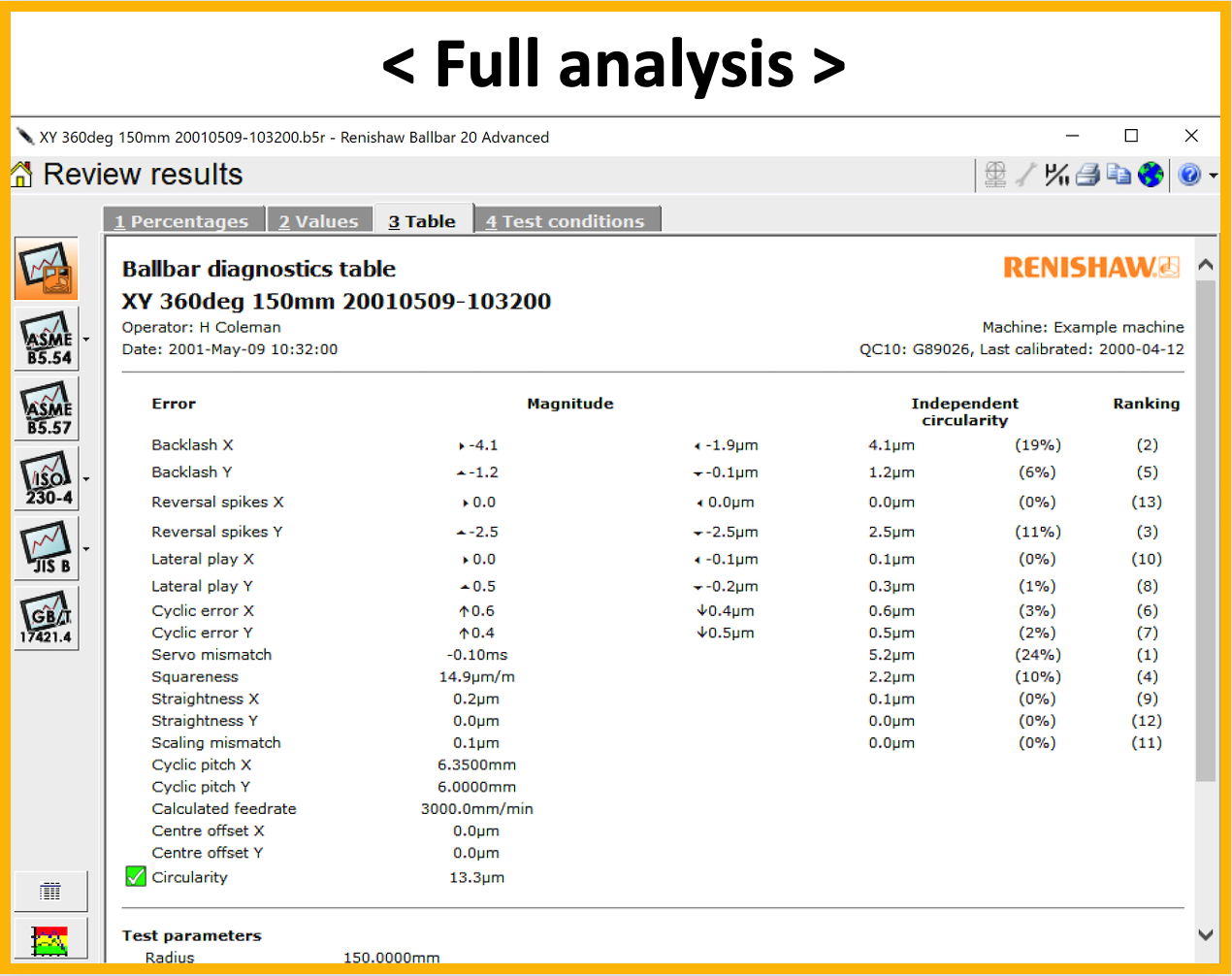

- Automatic capture data and quantitative analysis.

- Short running operation (around 10min/machine, for machining centre.)

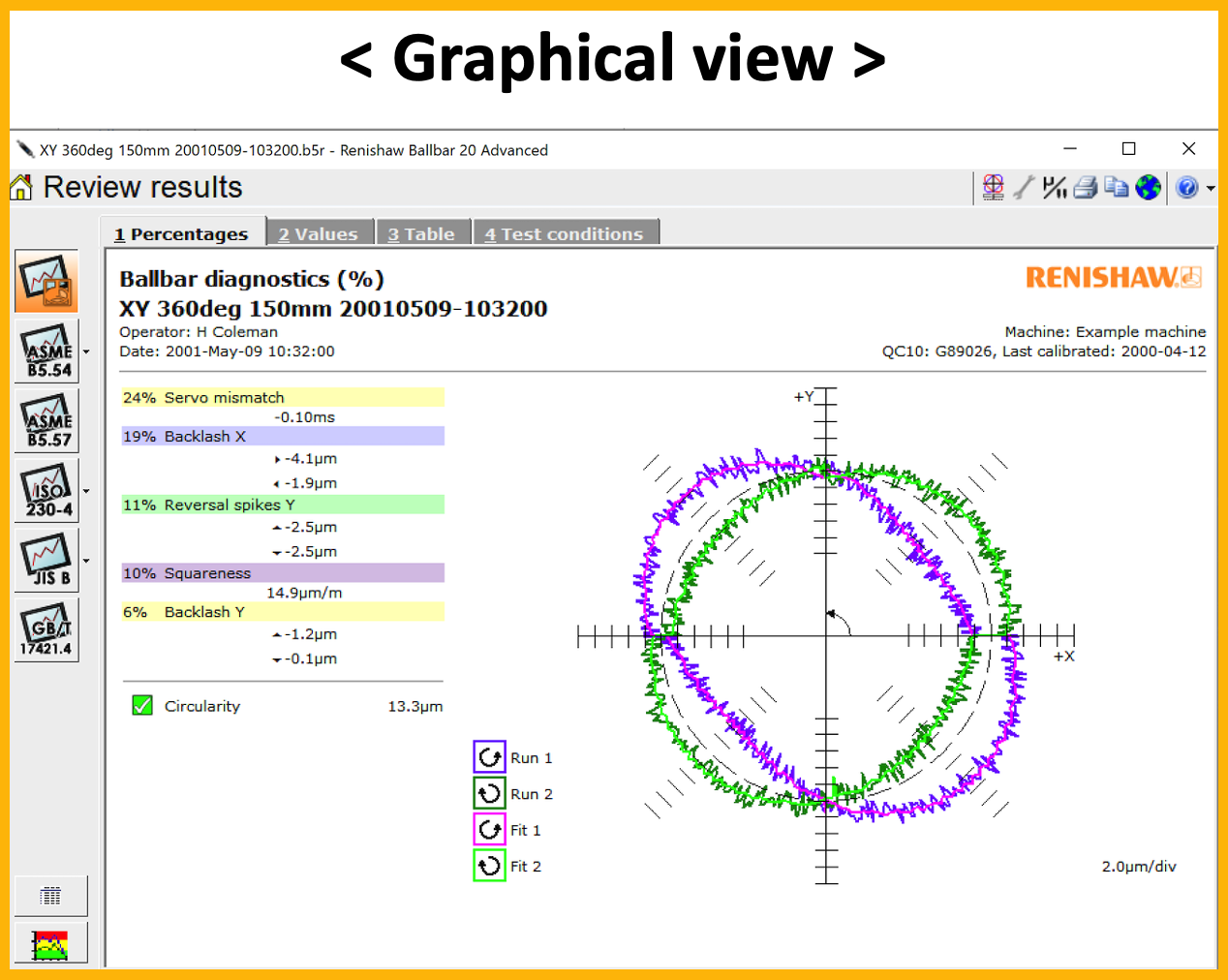

Analysis items :

Backlash, Reversal spikes, Straightness, Squareness, Scale error/mismatch, Servo mismatch, Cyclic error, Lateral error, and Circularity.

If you need more information,

- Website : https://www.renishaw.com

- QC20-W details : https://www.renishaw.com/en/qc20-w-ballbar-system--11075

- Contact us : https://www.renishaw.com/contacts/en/contact-us?productline=1&productname=QC20-W%20ballbar%20system