The 4 Concepts of MOLDINO to Achieve Mold Machining. Find out More about it at METALEX, Bitec Bangna, 22nd -25th NOV 2023

How to Achieve High-Quality Mold Machining

Through thorough quality control and innovation. We develop and stably provide high-value-added products,

service, and solutions that society can use safely and securely.

MOLDINO is providing innovative products that achieve higher machining quality with these challenges.

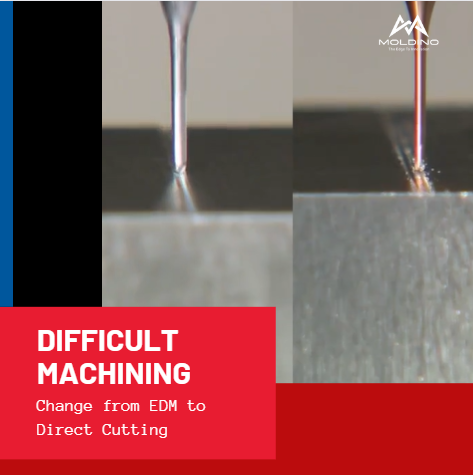

1. Difficult Machining

The Change from EDM to Direct Cutting helps create an effective cost reduction and total processing time.

The complex shapes can be achieved by "Direct Cutting" using MOLDINO Products and Original Machining strategy.

2. Hardened Material

The Harder Material, The More Difficult to Cut.

The tendency of material hardness for Die & Mold becomes Higher in HRC.

Only high-quality cutting tools can overcome this issue. The strong geometry and high heat resistance

are necessary for this machining situation. Not only to be able to cut the material but better mold quality results.

3. Mirror Finishing

We can reduce the polishing process and get high surface quality with direct cutting.

Hi-Pre2 concept is a concept that helps to improve surface quality right from the roughing process.

4. Ultra High Speed

Higher efficiency is always required in mold machining.

But Higher efficiency in mold production is even better. MOLDINO core concept " Production 50"

offer a strategy to achieve this requirement by innovative tools, special edge shape design, and advanced coating.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

.png)

Website: www.moldino.com

Youtube: MOLDINO Tool Engineering

Facebook: MOLDINO SEA, @Moldino Tool