High Efficiency Indexable Ball End Mill for Stamping Die and Welding Material

BR2P

Unique insert mounting mechanism and helical cutting edge for greater cutting efficiency

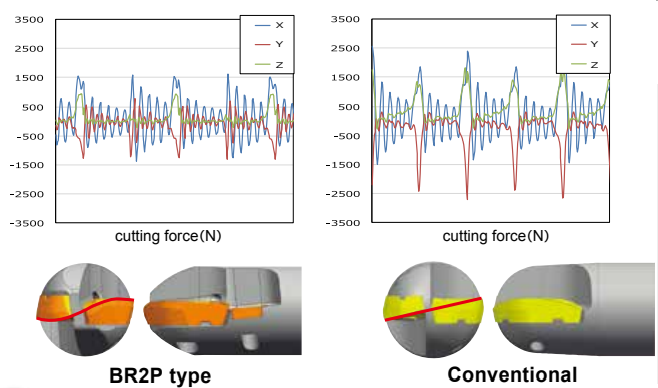

♦ Need to set less demanding cutting conditions when using conventional tools due to potential

for chattering vibration.

The shape of the helical cutting edge reduces cutting resistance, suppresses chattering by mitigating impact

on contact with the cutting edge, and helps prevent a rapid increase in cutting resistance.

Helical cutting edge to suppress chattering

Helical cutting edge to suppress chattering

The helical shape of the cutting edge results in improved tool life for BR2P than conventional products by suppressing chattering vibration

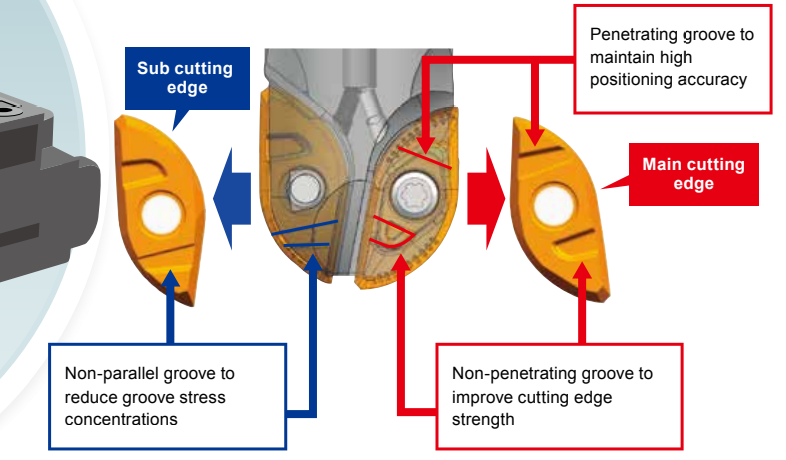

♦ Unable to increase cutting conditions, since more demanding cutting conditions could potentially damage the insert

A non-penetrating groove on the bottom surface of the main cutting edge secures cutting edge strength.

(The bottom surface of the main cutting edge receives the greatest cutting resistance.) In addition,

a penetrating groove on the constraint surface of the main cutting edge maintains high positioning accuracy.

Two-in-one integrated insert for improved convenience

Two-in-one integrated insert for improved convenience

Conventional products require two types of inserts (a main insert and a sub insert ). In contrast, BR2P uses a single integrated insert for improved handling.

.png)

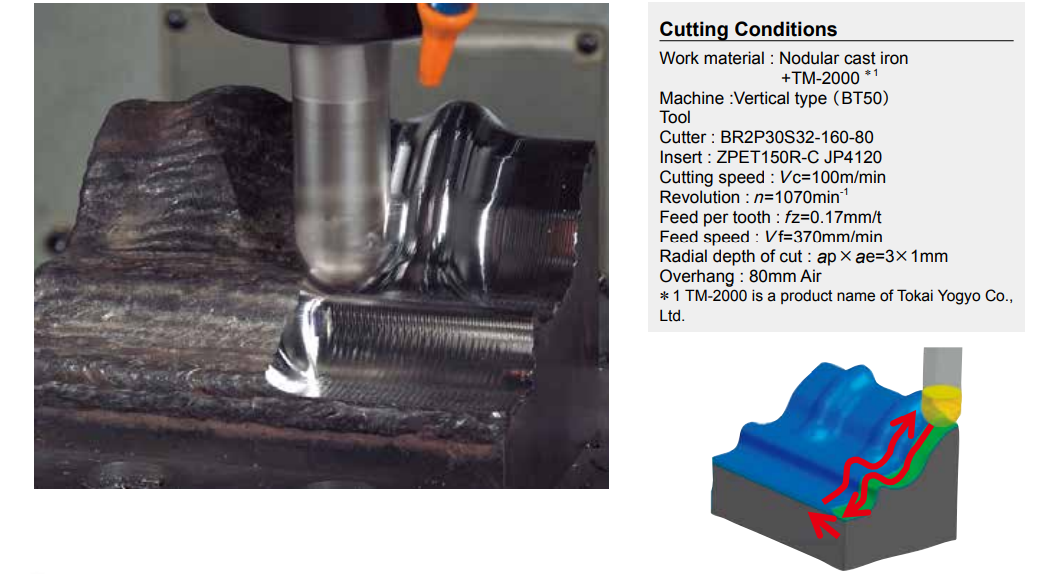

♦Tool life is reduced due to the difficulty in cutting the overlay welding material used for the press die repair. “Are there any suitable tools?”

The BR2P enables smooth cutting of overlay welding materials with variable cutting depths because the helical cutting edge suppresses cutting resistance even as cutting depth increases.

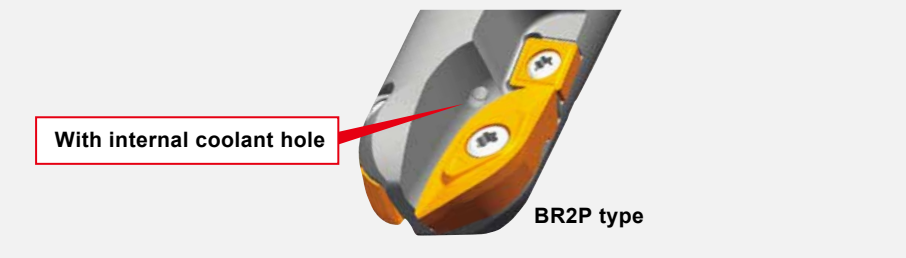

Internal coolant improves chip evacuation

Internal coolant improves chip evacuation

The BR2P has coolant holes for all diameters of the modular and shank types (except MT shank). The internal coolant improves the chip evacuation, reducing chip biting.

♦Is there a tool that can be used stably for the roughing cut of large-sized dies?

Large φ40 and φ50 tools are available for the BR2P. In addition, improved body and insert rigidity helps suppress chipping.

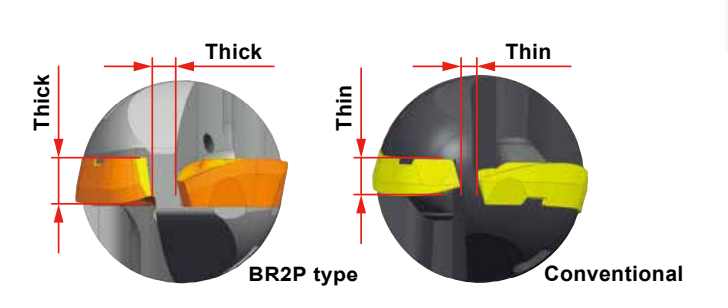

Increasing the body center thickness improves the rigidity of the body. Increasing the insert thickness enables to suppress

sudden chipping under higher efficiency machining.

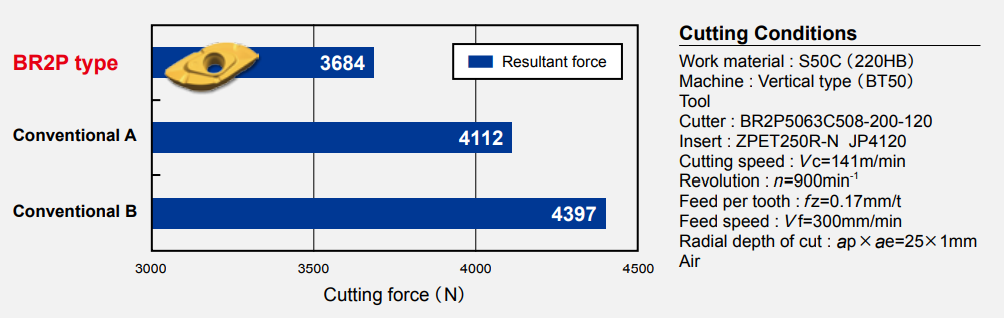

Nicked inserts reduce cutting resistance

Nicked inserts reduce cutting resistance

Using a φ50 nicked insert, the BR2P reduces cutting resistance compared to conventional products.

Product Info >> br2p_e.pdf (moldino.com)

Website www.moldino.com

Facebook MOLDINO SEA

http://web.facebook.com/MoldinoTool?_rdc=1&_rd

----------------------------------------------------------------------------------------------------------------------